Vote For American-Made, Vote4Energy

Mark Green

Posted March 3, 2016

Made in America is alive and well. In fact, U.S. manufacturers employ 9 percent of our workforce, or about 12.3 million workers. These companies – which make everything from cars and planes, to steel, fertilizers, furniture and clothes – remain critical to our economy. And, energy makes it all possible. Manufacturing accounts for more than 30 percent of U.S. energy consumption.

Energy isn’t just used to keep machines running or factory lights shining. It also provides the heat necessary to shape metal and the building blocks to create chemicals, refined fuels, plastics and fertilizers. Energy is the lifeblood of what we make, and affordable domestic energy is now providing an important leg up for domestic manufacturers. Thanks to the U.S. shale revolution, this newly affordable and abundant energy is making U.S. manufacturers increasingly competitive, or even more competitive, than overseas rivals. The shale revolution has reshaped the playing field and has made the U.S. the place to be for energy-intensive manufacturing. Jay Timmons, National Association of Manufacturers president and CEO:

“America has an unprecedented and incredible global advantage in reliable and affordable energy, and it’s driving manufacturing’s resurgence.”

To understand the sea-change energy is making in the manufacturing sector, you have to appreciate where manufacturing was a decade or two ago. In the 1990s, globalization took a toll on U.S. manufacturing. As emerging economies flexed their muscles, they increasingly became the world’s workshops. China, in particular, with cheap labor, cheap energy and lax environmental regulation, built its economy on manufacturing.

Competing against manufacturers in emerging economies was a tall order for U.S. industry. U.S. manufacturers shed more than 6 million jobs between the mid-1990 and 2010. However, as labor costs have risen overseas and U.S. manufacturing has regained its footing with new technology and more productive operations facilitated by affordable energy, the number of Americans working in manufacturing is growing again. Since 2010, U.S. manufacturers have added back more than 780,000 new jobs.

Because manufacturing is so energy intensive, access to cheaper energy can provide an important advantage. For example, energy can make up between 20 and 40 percent of the cost of steel production depending on where it’s made.

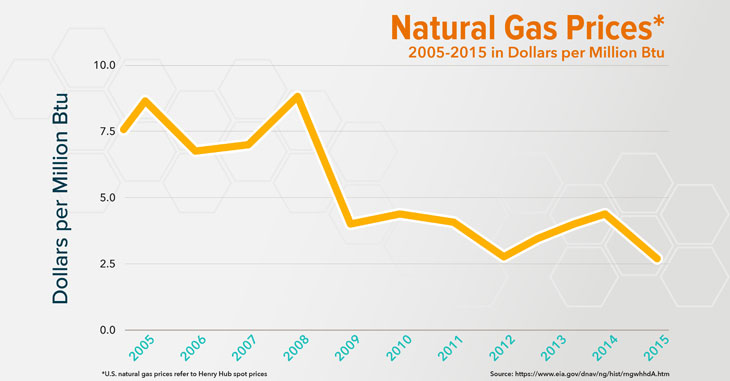

As domestic oil and natural gas production surged from the nation’s vast shale formations, the cost for key energy inputs has fallen. Oil production rose 70 percent since 2010, EIA says, while natural gas output has risen 23 percent. The growth in natural gas production, in particular, is important because of its role as a feedstock and as a fuel to generate heat and electricity – with gas costing 75 percent less than it did a decade ago.

The combination of rising labor costs in competing nations like China and Mexico and falling energy prices here has tipped the balance back toward U.S. manufacturers. Energy intensive U.S. industries like steel, paper and petrochemicals, for example, now enjoy power costs 30 to 50 percent lower than foreign competitors. According to recent research from the Harvard Business School’s Michael Porter and the Boston Consulting Group, thanks to lower energy prices, the cost to manufacture goods in the U.S. is now 10 to 20 percent cheaper than it is in Europe and nearly on par with costs in China. It’s believed that production costs could even fall below those in China by 2018.

“Thanks to the shale gas production boom, the United States is the most attractive place in the world to invest in chemical and plastics manufacturing. It's an astonishing gain in competitiveness.” - Cal Dooley

The importance of this shift in energy costs to manufacturing employment is seen in a 2014 PwC study, projecting that continued shale gas development in the U.S. could generate 930,000 new manufacturing jobs by 2030 and 1.41 million by 2040.

When energy prices fall, industry comes running. The surge in investment in manufacturing isn’t just coming from U.S. manufacturers. The change in fortune for U.S. manufacturing has been so great, foreign investment into the U.S is surging as well.

According to the American Chemistry Council, 246 investment projects have been announced in the U.S., valued at $153 billion. Remarkably, 60 percent of that investment is coming from overseas. The U.S. has become the place to be for the chemical industry. It’s estimated that this tremendous surge in investment could lead to more than 800,000 new U.S. jobs supported by the chemical industry by 2023. There are no ifs ands or buts about it, energy matters for manufacturing.

When we think about energy policy, it’s important that we understand that energy touches everything in our lives. Greater access to resources both on and offshore, as well as sensible regulations, affects the millions of Americans that work in the energy industry, consumers who pay for energy and businesses across the full breadth of our economy. Affordable and abundant domestic energy means a more competitive U.S. manufacturing sector and that means more well-paying American jobs.

About The Author

Mark Green joined API after a career in newspaper journalism, including 16 years as national editorial writer for The Oklahoman in the paper’s Washington bureau. Previously, Mark was a reporter, copy editor and sports editor at an assortment of newspapers. He earned his journalism degree from the University of Oklahoma and master’s in journalism and public affairs from American University. He and his wife Pamela have two grown children and six grandchildren.