Technology Moves U.S. Energy Ahead

Mark Green

Posted March 18, 2016

It doesn’t get enough notice: The U.S. energy renaissance is a revolution built on advanced technology and the ongoing quest to problem solve.

One of the best examples is hydraulic fracturing, the most important reason the United States leads the world in oil and natural gas production. Industry innovators took a process used for more than 60 years, modernized it and married it with it with advanced horizontal drilling to safely unleash previously inaccessible oil and natural gas reserves from shale and other tight-rock formations. It transformed America’s energy picture from one of scarcity and dependence to one of abundance and greater self-sufficiency.

The moral: When conventional wisdom says something can’t be done, just wait. Necessity, innovation and technology are marvelous at proving conventional wisdom shortsighted or wrong. On advancing new energy technologies to develop oil and gas more efficiently and in ways that are better for the environment, our industry isn’t standing still.

A couple more examples. First, let’s look at ExxonMobil’s Controlled Freeze Zone (CFZ) technology, the company’s breakthrough in carbon capture and storage (CSS). ExxonMobil’s Suzanne McCarron writes that the process targets world natural gas resources that contain large amounts of carbon dioxide (CO2):

While conventional technologies are unable to efficiently process natural gas with large concentrations of CO2, the CFZ™ technology has the ability to process natural gas with a wide range of impurities. The application of the CFZ™ technology at a global scale could therefore expand the pool of affordable clean-burning natural gas resources for development and delivery to consumers. The CFZ™ technology efficiently removes impurities from natural gas and is less expensive than existing technologies, requiring fewer processing steps and equipment. This increases its attractiveness, especially for offshore and remote applications.

The technology removes CO2 and hydrogen sulfide from natural gas in a special distillation tower that allows CO2 to freeze in a controlled manner, McCarron writes. The frozen CO2 then is melted and further distilled to remove valuable methane. Then it can be safely used for injection in dedicated wells, either for storage or to enhance oil recovery. In conventional CCS, CO2 is discharged at low pressure and must be compressed for injection into underground storage. The process is expensive. CFZ technology discharges CO2 as a high-pressure liquid, offering a strong commercial advantage.

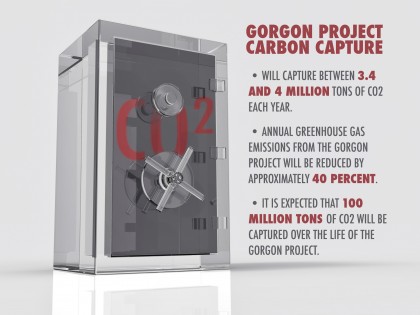

McCarron writes that ExxonMobil, which has a working interest in more than one-third of the world’s existing CCS capacity, is involved with the Gorgon Gas Project off Australia’s western coast. The company estimates that 100 million tons of CO2 will be captured over the project’s lifespan.

McCarron writes that ExxonMobil, which has a working interest in more than one-third of the world’s existing CCS capacity, is involved with the Gorgon Gas Project off Australia’s western coast. The company estimates that 100 million tons of CO2 will be captured over the project’s lifespan.

Also on the emissions front, ground has been broken in Texas for a power plant that will use a new natural gas system to generate low-cost electricity with zero emissions, including CO2. NET Power LLC says the 50 megawatt demonstration plant would the first of its kind in the world.

The company says Allam Cycle technology, which you can read about in-depth here, uses CO2 as a working fluid to drive a combustion turbine while eliminating all atmospheric emissions without needing CCS equipment. At the end of the process, the company says, pipeline-quality CO2 is produced that can be sequestered or used in various industrial processes, including enhanced oil recovery. NET Power CEO Bill Brown:

“NET Power is the first technology that allows policy and economics to work together, instead of against each other, to ensure the world meets our climate targets. Today marks a significant step for our world-class team, including Exelon, CB&I, 8 Rivers and Toshiba, towards delivering a technology that will be the cornerstone of a modern global energy infrastructure that is clean, affordable and flexible.”

According to NET Power, the system burns natural gas with oxygen (combuster pictured below) instead of air and uses high-pressure CO2 instead of steam to drive a turbine. The company says for a small reduction in efficiency the technology can operate without water – actually becoming a net water producer.

Again, just two of the many new technologies industry and its partners are developing to advance the safe, responsible use of the domestically produced fuels that drive our economy.

About The Author

Mark Green joined API after a career in newspaper journalism, including 16 years as national editorial writer for The Oklahoman in the paper’s Washington bureau. Previously, Mark was a reporter, copy editor and sports editor at an assortment of newspapers. He earned his journalism degree from the University of Oklahoma and master’s in journalism and public affairs from American University. He and his wife Pamela have two grown children and six grandchildren.